About Gyros Protein Technologies AB

Gyros Protein Technologies leads globally in the delivery of peptide synthesis and bioanalysis tools. They accelerate the discovery, development, and manufacturing of safer biotherapeutics through their provided solutions. Gyros Protein Technologies offers enabling tools that help researchers enhance the performance and productivity of biomolecules in drug discovery, preclinical and clinical development, as well as biotechnological applications. Gyros Protein Technologies sought a partner who could develop automated process equipment for two of their machines.

Automated production process with user-friendly mechanics

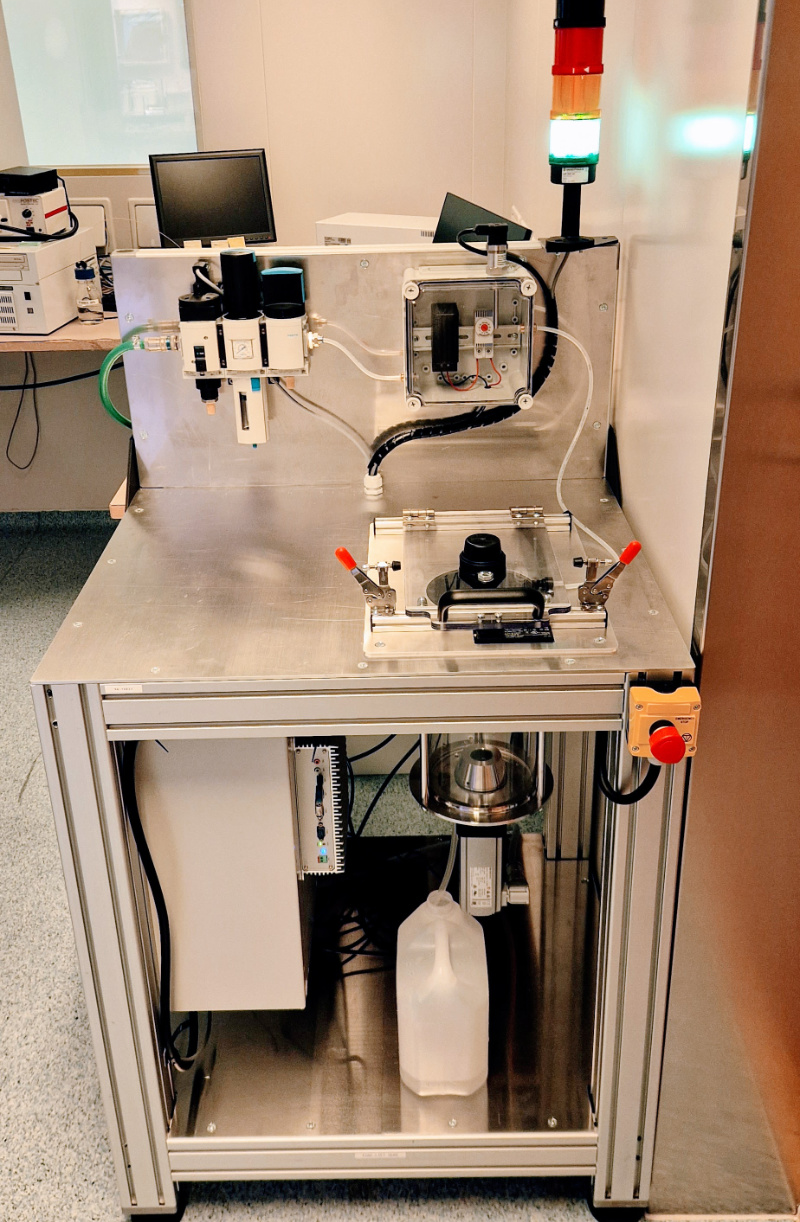

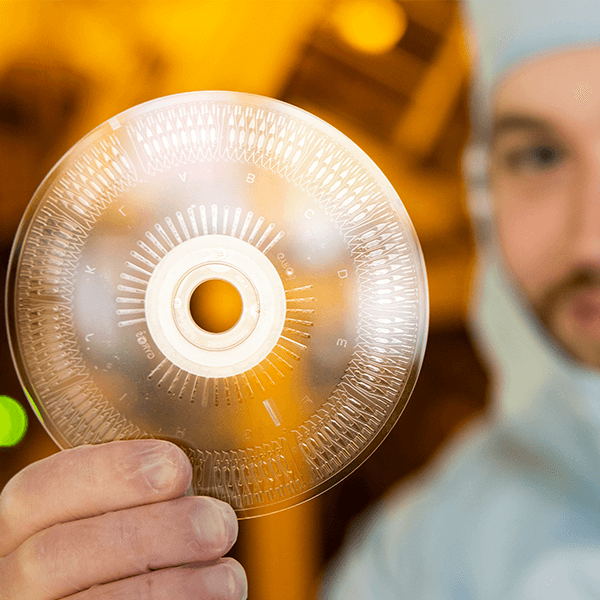

The production process for Gyrolab Bioaffy CDs from Gyros Protein Technologies includes several steps. NEP have built a machine that automates two of these steps. All data from the process is logged and stored on the computer for future reference and troubleshooting if a problem arises later in the production process.

Gyros already had clear requirements and a deep understanding of how their production steps should be carried out to ensure the correct function of their product. At NEP, we initiated the collaboration with a preliminary study to specify the tasks and the timeframe for implementation. Our mission was to automate parts of Gyros' production process by developing two machines that were safe, reliable, and user-friendly.

”Vårt samarbete med NEP har präglats av lyhördhet och problemlösning. Scope-ändringar och alternativa problemlösningar har beslutats i samförstånd. Kunskapsnivån har varit hög både på mjukvarusidan och hårdvarusidan. Sammanfattningsvis är vi nöjda med vårt projekt tillsammans.”

– Robin Lundberg, Production Manager, Gyros Protein Technologies

Today, the final software has an easy-to-use user interface with settings for all relevant variables, making it easy for Gyros' staff to add a new product or manage an old product that needs adjustment.

At NEP, we took responsibility for and developed all mechanics, electrical wiring, and software design. In addition, we were responsible for the assembly and transport of the machines.

We delivered the machines with comprehensive manuals aimed at both users and service personnel. These manuals are expected to help them take care of the machine in the production environment at Gyros.

The responsible project manager at NEP shares insights about the project

The project itself was complex. Here, Niclas tells more about how he experienced the collaboration and the development of the machine for Gyros Protein Technologies:

"It was an exciting and enjoyable project from day 1. Personally, I had a lot of room to be creative within the constraints of the machine's requirements in my role as a mechanical designer. It was also enjoyable to involve the customer in the project through my role as a project manager and to present the project's progress every week and bounce off ideas with Gyros' own team. The result of a good collaboration was a couple of really great machines."

- Niclas Rasmusson, Project Manager and Mechanical Designer at NEP

Product Category

• Industrial Engineering and Industrial Production Equipment

Technical Areas

• Mechanical and Industrial Design, Software, Industrial Electronics, Automation