We work together with you and your team on everything from simple applications to complex integrations. With us, you can choose which part of the product cycle you need. We offer a range of products and services within the scope of product development, product care, test systems, as well as manufacturing and testing. You can find the information you need below.

NEP specializes in product and system development. We also conduct life cycle analyses and assist with certifications such as EMC and LVD, ensuring compliance with industry standards.

We handle your released products, address component shortages, or support redesign needs. We assist with customer returns and conduct technical investigations to ensure optimal performance.

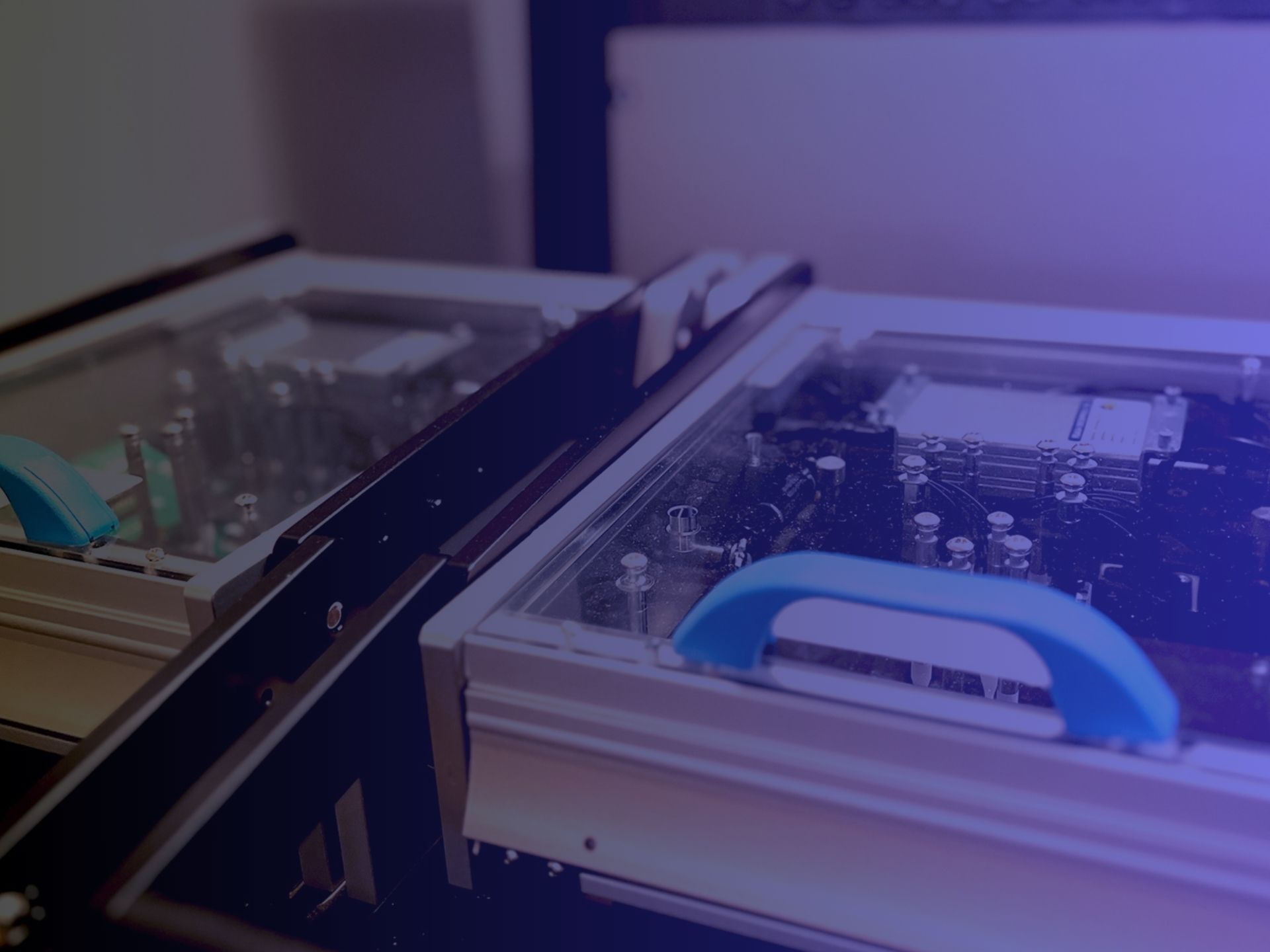

We provide tailor-made test systems to ensure high production quality. Additionally, we can develop cost-effective standardized test systems. With NEP TestNet, you gain real-time visibility into production.

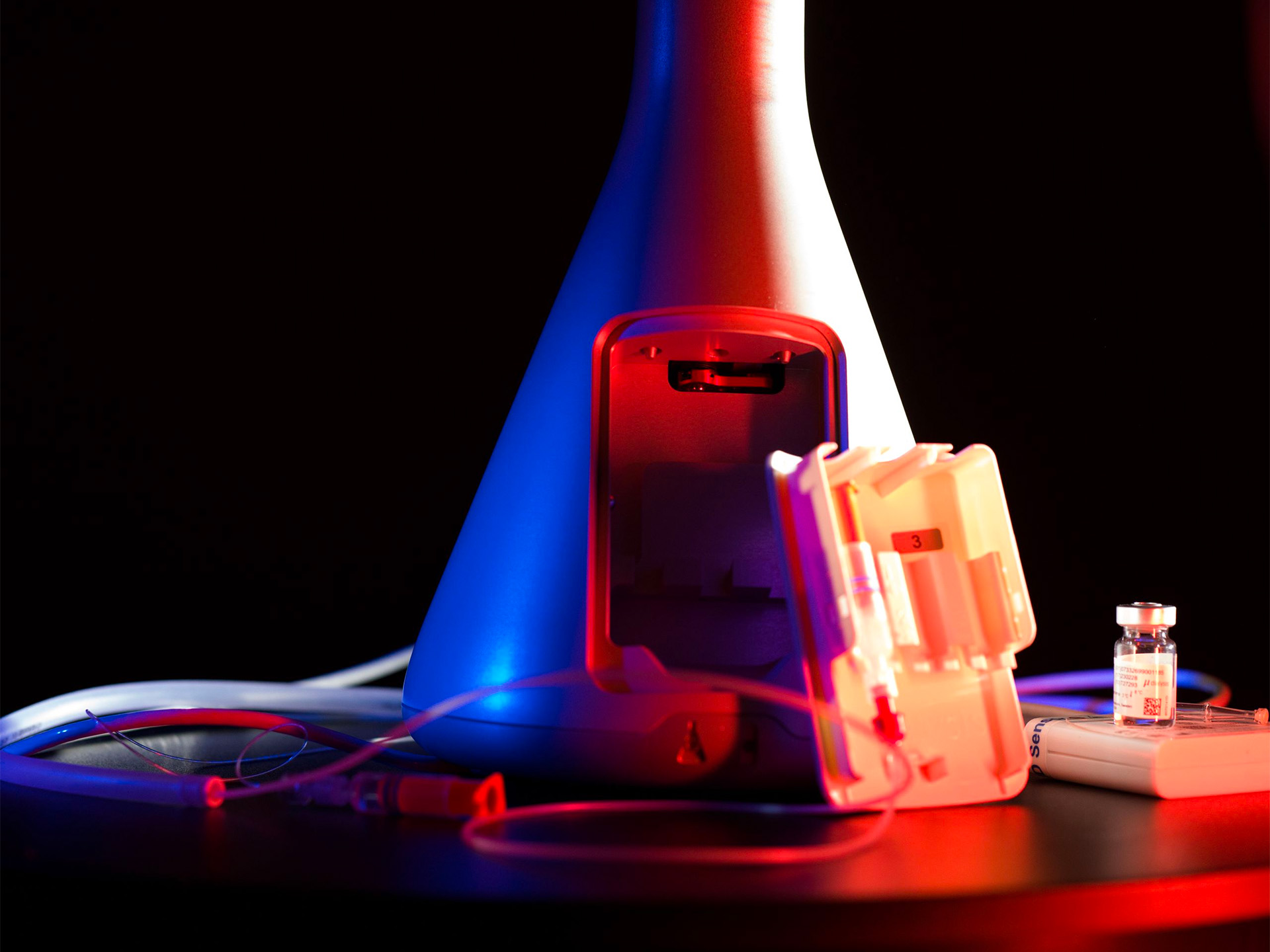

Ensure that even small volumes receive high attention. We have specialized our production for prototypes and small series. We aim to provide you with valuable DFx feedback on your product. Additionally, we offer a test hub that verifies the desired quality and flawlessness of the product.

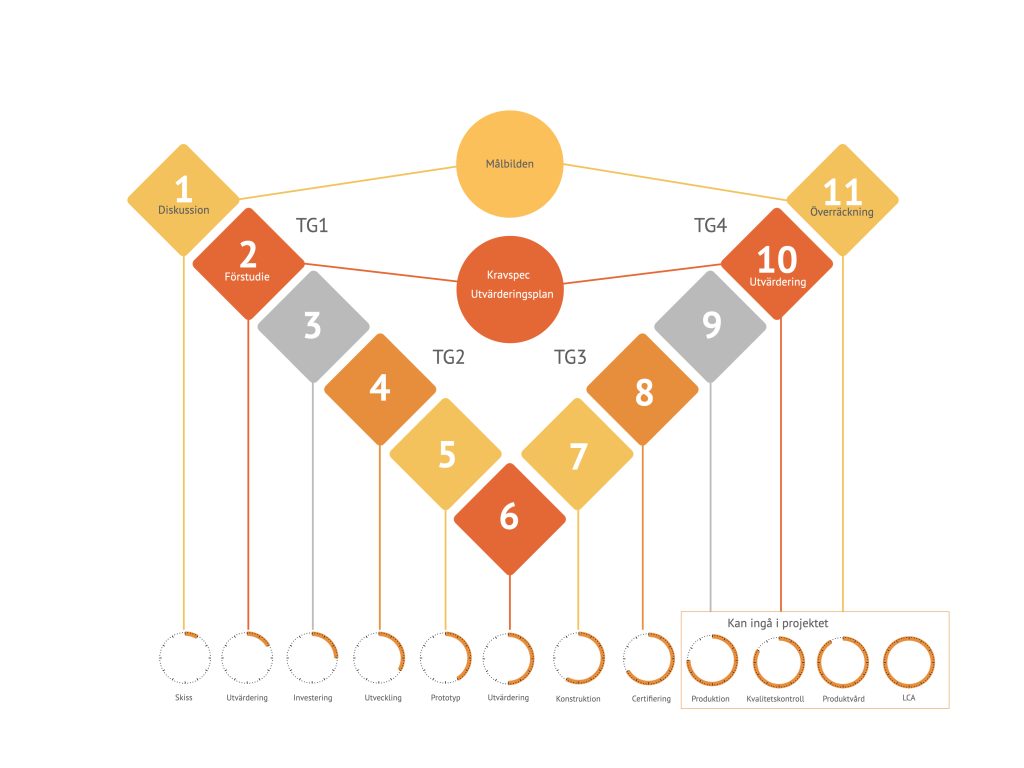

During product and system development, you will find our unique development model and what we offer in projects.

The regulations regarding the environmental footprint of your product are becoming increasingly stringent. NEP also has the tools to help you with a life cycle analysis (LCA).

NEP assists with certifications such as EMC and LVD. We are certified according to ISO 13485 and ISO 14001.

Technical evaluations are for those who are investing in a product and want to understand its technical solutions. This may also involve certification or environmental considerations.

Our engineers, along with an entire network of various competencies, can assist you in finding the right components, replacing components, and solving issues in development and manufacturing.

In case of production issues or field returns, we assist with technical investigations to understand the root cause of the problem and develop solutions for both short and long term. 8D reports are routine for us.

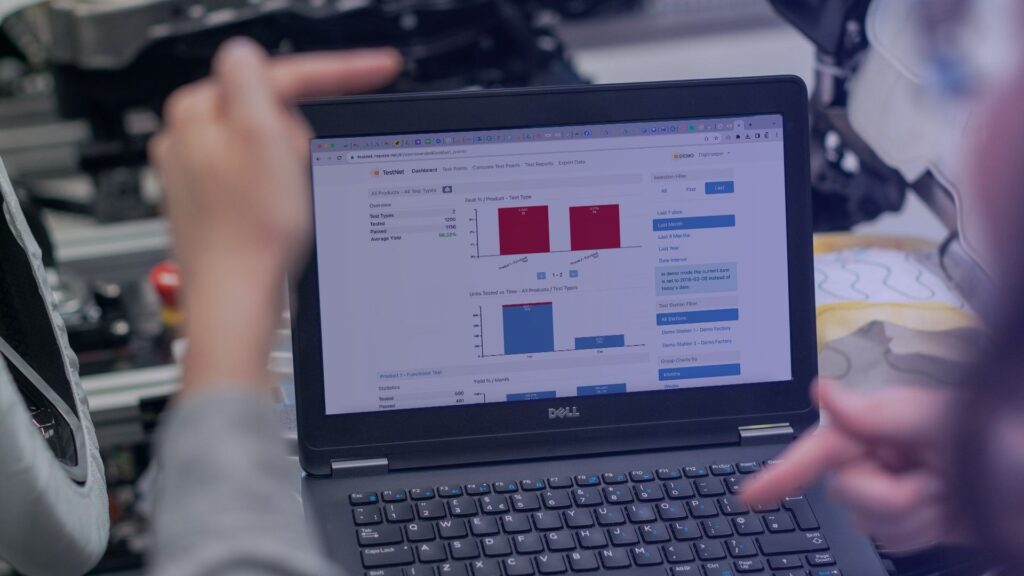

With NEP TestNet, you get an insight into production and control over daily yield, enabling you to trace faulty units and batches. You can also visualize production rates.

Get an immediate view of the status of each case. Comment directly on our Kanban board if you want to reprioritize, create a new case, etc. 'NEP Insight' is your window into NEP's operations.

We assist you in reducing the cost of your product, finding more economical solutions, simplifying manufacturing, and identifying alternative components and suppliers.

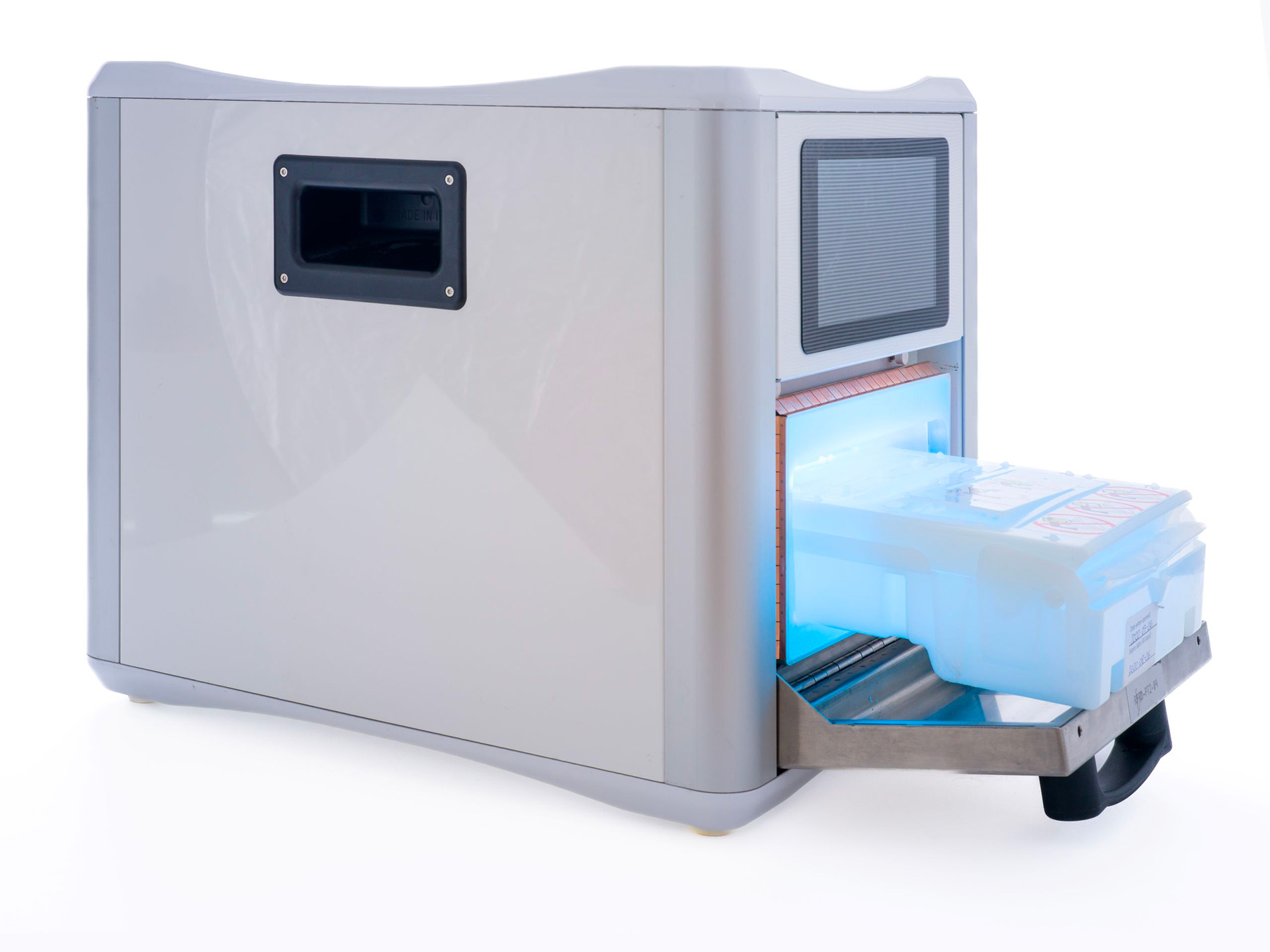

RTS is a high-performance testing solution for efficient product testing. Flexible, automated, and cost-effective.

ETS (Embedded Test System) offers efficient and customized solutions for quality testing of embedded systems. Optimized performance and reliability.

Monitor the production of your products without being physically present. What are the trends? When was the crucial batch tested? What is the most common cause of errors? All the information you need is easily accessible through NEP-TestNet.

We build test systems that are entirely customer-specific and tailored to your requirements for quality control in production. This could include visual inspection, pressure measurement, or customization for your production line.

You have just developed a product with us. In the initial stage, you cannot start mass-producing 1000 units but need to test the market. This is where our small-scale project manufacturing fits; here, we can produce 1-10 units at a time.

Efter vi utvecklat en testlösning till er tar vi gärna hand om testutförandet för kortare eller längre period. Med våra egna system och kundens fixturer utför vi operativ testning, denna tjänst passar bra tillsammans med tillverkning samt Produktvård.